What Is DTF Printing? Everything Explained Simply

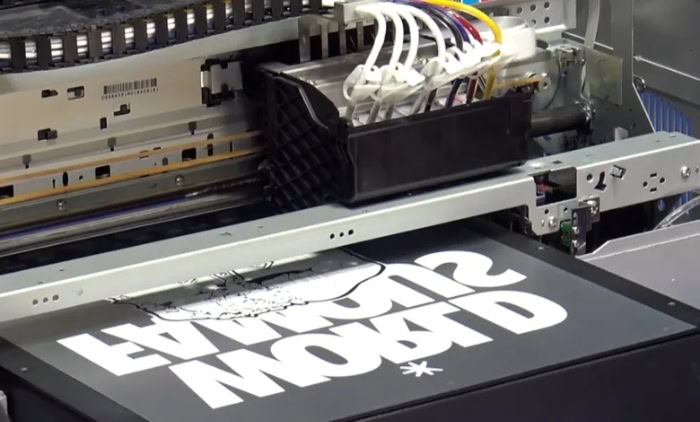

Bright, detailed prints on T-shirts, tote bags, and even hard surfaces are taking over the world of custom merchandise, and DTF printing is at the heart of this creative boom. Standing for Direct-to-Film, DTF printing has quickly gained a reputation for its flexibility, bringing professional-quality designs within reach for small businesses, hobbyists, and large-scale producers alike.

Unlike older methods that limit your design options or require complex setup, DTF offers a fast, reliable way to create vibrant, durable prints on a wide range of materials. With more designers and entrepreneurs turning to DTF printing for its affordability and versatility, this method is redefining what’s possible in the world of textile decoration and beyond.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing stands out as a contemporary method for creating vibrant, customized designs on a wide variety of surfaces. With its simple yet highly effective process, DTF has attracted both newcomers and seasoned professionals in the world of textile decoration.

Whether you’re aiming to produce just one shirt or a large batch of promotional items, DTF printing offers an appealing balance of flexibility, quality, and ease of use. To appreciate how this technology works, it helps to look at the core process, essential materials, and the detailed workflow that brings creative visions to life.

Definition and Core Process

DTF printing refers to an innovative workflow that transfers digital designs directly onto special films before applying them to final products. The core idea behind DTF is straightforward: create a digital design, print it onto a clear or semi-transparent film, and then use heat to transfer the image onto a chosen material.

Unlike some older techniques that print directly onto fabric, DTF uses a film carrier, giving users precise control over design placement and compatibility with a wide range of materials.

Essential Components

A successful DTF print relies on a handful of specific components working in harmony. The process begins with PET (polyethylene terephthalate) film, which serves as the temporary carrier for the printed design.

Specialized DTF inks, usually including cyan, magenta, yellow, black, and a standout white ink, create rich, opaque images. White ink in particular is crucial, as it allows for bright, true-to-design colors even on dark or colored fabrics.

Adhesive powder plays an important role by bonding the ink to the material during heat transfer. Curing equipment such as specialized ovens or heat presses ensures that the adhesive and inks reach the right temperature for a durable result.

Each of these materials is engineered to work together, resulting in prints that are both vibrant and long-lasting.

Step-by-Step Workflow

The DTF printing process unfolds in a few carefully-coordinated steps, each contributing to the sharpness and durability of the final print. It all begins with digital artwork, which is sent to a specialized printer loaded with DTF inks.

The printer deposits the ink in mirror image onto the PET film, layering white ink underneath the colors when the artwork calls for opacity or vividness.

While the ink is still wet on the film, adhesive powder is evenly sprinkled over the design. Any excess powder is gently removed, ensuring that only the printed areas are covered.

The film with ink and powder then moves to a curing stage, either by passing through a curing oven or under a heat press for a short period. This step melts the adhesive, preparing the print for transfer.

Once cured, the film is positioned over the target substrate, such as a T-shirt or tote bag. A heat press applies firm, even pressure at a specific temperature, causing the adhesive to bond the ink permanently to the surface.

When the film cools, it is peeled away, revealing a vibrant, durable design that feels soft and holds up well to washing and wear.

Through this streamlined workflow, DTF printing provides a straightforward yet powerful way to apply detailed, colorful designs to a range of materials with minimal setup and consistently impressive results.

DTF vs. Traditional Printing Methods

Choosing the best printing technique can make a significant difference in terms of quality, cost, and creative freedom. DTF printing competes with established methods like Direct-to-Garment (DTG) and screen printing, each bringing unique strengths and challenges.

By understanding how DTF compares with these traditional techniques and learning about hybrid approaches, creators and businesses can find the right match for their specific projects and goals.

DTF vs. DTG (Direct-to-Garment)

DTG printing is well-known for producing detailed, colorful prints directly onto fabric, particularly cotton. DTG methods shine when working with light-colored cotton garments and intricate designs that require subtle gradients or photo-realistic effects.

However, DTG faces limitations on dark fabrics unless pre-treated, and prints often struggle with synthetic materials like polyester or blends.

DTF printing steps ahead with its wide material compatibility. Cotton, polyester, blends, and even non-traditional surfaces can all receive a high-quality print.

No need for pre-treatment, even on dark or synthetic items, thanks to the use of white ink and adhesive powder. In terms of color range, both methods perform well, but DTF often produces more vibrant prints on a wider array of substrates.

From a cost perspective, DTF generally offers lower production costs for short runs or single items, as no pre-treatment or direct fabric handling is needed. Maintenance and downtime for DTF equipment also tend to be less demanding compared to DTG setups.

DTF vs. Screen Printing

Screen printing remains a go-to choice for large quantities and single-color or simple multicolor designs. Its ink-through-mesh technique delivers unmatched durability and saturation, especially for bulk orders.

However, achieving photo-quality images or complex gradients can be tricky, requiring separate screens and meticulous alignment for each color. Setup time and costs are high for small runs, making screen printing less flexible for short, custom orders.

DTF eliminates much of the setup hassle. There’s no need to create screens or manage messy inks, so even one-off designs or frequent changes pose no issue.

DTF excels with sharp details, gradients, and photographic elements, and the process supports vibrant, multi-color prints without extra steps. For large-scale production, screen printing still leads in speed and overall cost.

Yet for mid-sized runs, custom items, or intricate designs, DTF offers a balance of flexibility, convenience, and quality that screen printing often can’t match.

Hybrid Applications

Creative printers increasingly blend DTF with traditional methods to push the limits of their designs. For example, a screen-printed garment might feature a DTF transfer for photographic highlights, metallic effects, or other complex graphics that are too labor-intensive for screen printing alone.

Some studios use DTF overlays to personalize mass-produced base prints, giving each item a unique flair without disrupting the main production flow.

Combining technologies opens the door to unlimited creative options. DTF can complement or enhance output from DTG and screen printing, making it easier to experiment with new techniques or address special requests from customers.

By mixing methods, printers take advantage of each approach’s strengths, crafting products with both efficiency and artistic impact.

Key Advantages of DTF Printing

Direct-to-film printing has quickly found favor among creatives, small businesses, and established brands for several compelling reasons. Its unique approach to decoration makes it possible to tackle a wide range of projects with impressive speed and outstanding results.

The advantages of DTF printing go beyond just visual appeal, touching on practicality, cost-efficiency, and overall performance.

Material Versatility

A major strength of DTF printing is its unmatched compatibility with a broad spectrum of materials. Cotton and polyester garments print equally well, unlike some traditional methods that struggle with synthetic fibers or require special pre-treatment.

Even blended fabrics turn out crisp, colorful results without extra steps. DTF’s flexibility doesn’t stop at fabrics; it also works on non-traditional surfaces like wood, metal, and certain plastics.

This capability allows businesses and independent creators to expand their offerings beyond just apparel, producing everything from customized tote bags to branded signs and unique promotional items.

Small-Batch Viability

Not every order requires hundreds of identical prints. DTF printing thrives in scenarios where flexibility and low setup costs matter most.

With no need to create screens, mix inks, or prepare large runs, even a single custom shirt or small, varied batch can be produced quickly and affordably. This advantage levels the playing field for startups and artists who want to test new ideas or offer personalized products without the risk of overproduction or high initial investment.

Customers benefit from true on-demand service, and creators retain full control of their production schedules.

Durability

Lasting quality is a must for decorated textiles and promotional merchandise. DTF prints are engineered for tough use; they resist cracking, fading, and peeling even after repeated washing and regular wear.

The combination of robust inks, specialized adhesives, and precise heat-curing results in designs that retain their vibrancy and integrity over time. This durability ensures that finished products keep looking new, which translates into customer satisfaction and enhanced brand reputation.

From gym bags to workwear, DTF decorations stand up to everyday life and the challenges that come with it.

Challenges and Limitations

While DTF printing provides remarkable advantages, it is important to recognize the challenges and operational demands that come with adopting this technology. The hurdles range from upfront investment requirements to technical demands and environmental considerations.

Equipment Costs

Getting started with DTF printing involves more than just a standard printer. Specialized DTF printers are required, along with powder shakers for applying adhesive evenly and reliable heat presses to ensure proper bonding.

Each piece of equipment represents a significant financial outlay, especially for those launching a business or expanding from a hobbyist setup. Maintaining machinery and purchasing compatible consumables like inks, films, and powders add to the ongoing costs.

Small operations may find this investment daunting at first, especially when compared to less equipment-heavy decorating methods.

Technical Learning Curve

Running a DTF setup smoothly calls for more than basic technical skills. Mastery in color management is essential for achieving vibrant and accurate results, particularly when printing detailed or multi-hued designs.

Consistency with adhesive powder application is another crucial element; uneven or insufficient coverage can ruin a print’s durability or appearance. Curing must also be handled with precision, as incorrect temperatures or timing compromise the transfer and longevity of the image.

Developing expertise across all stages of the process takes time and patience, and beginners may experience setbacks as they refine their workflow.

Environmental Considerations

DTF printing’s reliance on PET film introduces concerns about plastic waste. Each print typically uses a new piece of film, contributing to single-use plastic consumption.

While many studios strive to minimize waste or recycle where possible, the environmental footprint remains higher than some direct printing approaches. Additionally, DTF’s need for heat presses and curing ovens drives up electricity use, impacting both operational costs and sustainability.

Conscious creators and brands may need to weigh these factors carefully or invest in strategies that help offset their ecological impact.

Applications and Creative Possibilities

DTF printing has rapidly broadened the creative landscape for designers, entrepreneurs, and hobbyists. Its adaptable process supports everything from personalized gifts to large production runs, making it an excellent choice for businesses seeking to diversify their product lines or artists eager to experiment with new formats.

Apparel

Custom apparel remains one of the most popular uses for DTF printing. Designers create vibrant T-shirts, eye-catching hoodies, and on-trend athleisure wear with stunning color detail.

Because DTF works equally well on cotton, polyester, and fabric blends, brands have the flexibility to offer collections on a wide variety of garments. Soft prints that stretch with movement and endure frequent washing appeal to consumers who value both style and comfort.

The on-demand nature of DTF production also supports small business ventures and independent labels looking to release limited-edition or highly personalized designs without the burden of large minimum orders.

Non-Apparel Uses

Opportunities for DTF printing extend far beyond clothing. Promotional merchandise, such as branded tote bags, event banners, caps, and even posters, all benefit from the precise and colorful output that DTF provides.

Marketers and event organizers use DTF to bring logos, slogans, and vibrant graphics to a range of surfaces, making their campaigns or celebrations more memorable. Artisans and small businesses often use DTF on wood, metal, and select plastics to create unique home décor, signage, or novelty items.

The ability to personalize products in small batches makes DTF particularly attractive for gift shops and online sellers catering to custom requests and seasonal trends.

Design Flexibility

DTF technology supports unrivaled design freedom, handling everything from subtle gradients and tiny text to photorealistic images and intricate patterns. Vivid color reproduction and accurate detail mean that even the most complex designs maintain their impact on diverse substrates.

Designers can experiment with overlays, layering effects, and texture simulations, knowing that the process will translate their vision onto almost any surface. The possibility to quickly test new artwork and iterate on designs opens the door to rapid creative development, making DTF ideal for trend-driven markets and artists who thrive on experimentation.

With its rich palette, material compatibility, and support for intricate artistry, DTF printing is powering a new era of creativity and custom manufacturing. Its applications are only limited by imagination, making it a favorite for both business innovation and personal expression.

Conclusion

DTF printing represents a compelling blend of creativity and practicality for anyone looking to make their mark in textile and merchandise decoration. Its ability to print vibrant, long-lasting images on a remarkable variety of materials, and in any quantity, has opened doors for small startups, artists, and established brands alike.

With lower setup barriers, design freedom, and strong durability, DTF enables fresh ideas to become reality with fewer limitations. While challenges such as equipment investment, technical skill, and environmental concerns remain, the opportunities for innovation and unique product offerings continue to grow.

For those eager to stand out in an increasingly personalized world, DTF printing offers the flexibility, reliability, and creative potential to turn bold concepts into tangible success.