Prebuilt vs. Custom PC: Pros, Cons, and What to Expect

Building your own PC or choosing a prebuilt machine is more than a debate about specs. It reflects shifting prices, supply challenges, and how users approach their tech.

Gamers, creators, and everyday users face a maze of sticker prices, hidden costs, performance gaps, and evolving support needs. Bulk-purchasing power can let prebuilt vendors offer competitive pricing, yet custom builders often chase that last ounce of performance or future-proofing.

Meanwhile, quality-of-life factors like time to set up, warranty support, resale value, and upgrade ease can tip the scales in unexpected ways. The optimal choice hinges on priorities: chasing raw value, craving convenience, or future-proofing your investment.

Total Cost of Ownership

Selecting between a custom-built PC and a prebuilt system often begins with a deep look at the true costs involved, far beyond just the up-front price tag. While the sticker price may draw attention first, additional expenses and long-term value can have an even greater impact on your wallet.

Looking at all elements of cost, including hardware pricing, hidden expenses, and resale prospects, offers insight into what buyers are really paying for.

Hardware Pricing Dynamics

Mass-market system integrators often source components directly from manufacturers in huge quantities. This purchasing power typically qualifies them for substantial bulk discounts unavailable to everyday consumers.

Combined with tight profit margins, assemblers can offer prebuilt PCs at prices that sometimes rival or even undercut the cost of buying comparable components at retail. For DIY builders, retail pricing almost always means paying the full price for each part, without bundle deals or volume-based savings.

Sometimes, the gap narrows during seasonal sales, but overall, suppliers of prebuilt rigs leverage economies of scale to stay competitive. However, OEM parts in prebuilts may differ slightly from the full-featured retail versions available to custom builders, which can influence both performance and value.

Hidden & Follow-up Expenses

Beyond the big-ticket items, several often-overlooked costs await. Custom PC builders must factor in tools such as screwdrivers, anti-static wrist straps, and thermal paste, especially for first-timers without an existing toolkit.

An operating system license, cables not already included, and shipping from multiple vendors can further inflate the final bill. For prebuilts, expenses might sneak in via sales tax, or even through bloatware that arrives pre-installed and requires time or expert help to remove.

Upgrading components after purchase may require additional fees or void warranties, creating another potential drain on your budget. Shipping on prebuilts is usually consolidated and sometimes subsidized, but hidden fees can still arise, particularly with large or heavy systems.

Resale & Depreciation Considerations

The long-term value of a PC doesn’t end at the point of purchase. For custom PCs, using standard parts means components can be sold off individually or as a full system if an upgrade or cash is needed.

Standard components usually retain more of their value, since buyers can trust what they're getting and easily research compatibility. In contrast, prebuilts sometimes contain proprietary parts such as motherboards or power supplies that restrict reuse and lower the chances of a good resale.

These unique or non-standard components can depreciate faster and may deter potential buyers, leaving owners with fewer ways to recoup their initial investment. Taking depreciation and resale potential into account can reveal a very different picture of overall value between custom and prebuilt machines.

Performance and Component Quality

Comparing prebuilt and custom PCs often centers on performance and the grade of parts each system uses. Hardware may look similar on a spec sheet, but actual user experience can differ in important ways.

System builders and individual tinkerers each approach selections and assembly differently, and the results show up in benchmarks, thermals, and everyday reliability.

Spec Transparency

Clear and transparent specifications are a hallmark of custom-built PCs. Selecting each part personally allows buyers to know the exact model numbers, production revisions, and feature sets.

Custom parts lists also make it easy to research compatibility and reliability. By contrast, prebuilt systems sometimes use components that are exclusive to large OEMs or slightly altered versions of retail hardware.

Part numbers may be vague, and it’s possible for a graphics card or power supply to look similar to its retail counterpart but differ in cooling, power delivery, or manufacturer warranty. Down-binned or OEM-only parts might not deliver the same sustained performance or upgradability, which can complicate research and comparisons for buyers aiming to maximize value.

Thermals, Noise, and Power Delivery

Cooling and noise control are important aspects of the user experience. Custom PC builders often select after-market CPU coolers and cases designed for optimal airflow.

The result is more consistent thermal performance, lower fan noise, and often higher boost clock stability during heavy gaming or workstation use. Prebuilt systems generally use factory-set fan curves and compact chassis that prioritize space saving or shipping efficiency.

These systems may run hotter or louder, especially under sustained load. Additionally, some prebuilts use power supplies and motherboards with limited headroom or upgradability, impacting power delivery and, by extension, overall performance potential.

Benchmark Comparisons

Performance numbers at a similar price point tell much of the story. Custom PCs frequently achieve a slight edge in gaming frame rates or productivity workloads, thanks in part to better component selection and more robust cooling.

Beyond raw numbers, BIOS settings and multipliers are essential for unlocking hardware potential. Prebuilt manufacturers sometimes restrict BIOS options or lock multipliers, limiting the user’s ability to overclock or tune for efficiency.

As a result, real-world testing often reveals small but consistent differences in how smoothly the systems run, how well they maintain clock speeds over time, and how loud or warm they get under stress. For competitive users or professionals, these subtleties can have a noticeable impact, while mainstream buyers may prioritize stability and quiet operation.

Convenience, Time, and Skill

Convenience often becomes a deciding element when choosing between a custom build and a prebuilt PC. Time, required expertise, and product availability all play important roles in shaping the user’s experience.

Some buyers want a seamless, hands-off process, while others value the pride and knowledge gained from assembling their own machine.

Assembly & Setup Time

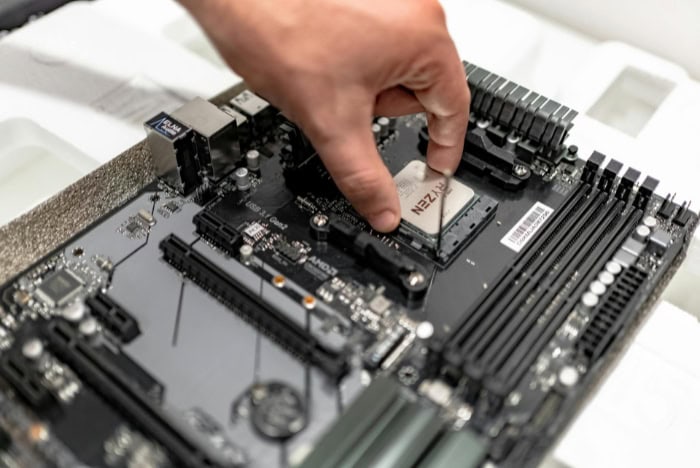

Building a PC from individual parts can be a demanding process, especially for those with little experience. Assembling components, routing cables, mounting storage, and applying thermal paste require patience and careful attention.

It is not uncommon for a first-time builder to spend several hours, sometimes an entire afternoon or even a weekend, completing a custom system. Troubleshooting any issues or mistakes can further extend the process.

Prebuilt PCs deliver simplicity by arriving fully assembled, tested, and ready to go. Unboxing a tower, plugging in peripherals, and finishing a brief software setup often has buyers gaming or working within an hour.

The convenience of avoiding a lengthy build can appeal to those with packed schedules or limited technical confidence.

Learning Curve & Risk

First-time builders face a distinct learning curve. Correctly installing parts calls for precision and an understanding of how sensitive electronics interact.

Cable management, static electricity precautions, and BIOS updates can feel intimidating. Mistakes risk component damage or hours spent troubleshooting why a system fails to boot.

Prebuilt systems are assembled and quality tested by professionals, reducing risk and offering near-guaranteed out-of-box functionality. For anyone not interested in mastering the minutiae of PC assembly or for those who simply prefer a plug-and-play experience, prebuilts offer reliability and peace of mind.

Availability & Supply Chain

Hardware shortages and supply chain disruptions can slow down the building process. Sometimes, the exact GPU, case, or other desired part is backordered or available only at a mark-up, causing long delays.

Multiple shipments from separate retailers can stagger arrivals and add to wait times. Large system integrators have established supplier relationships and can sometimes secure high-demand components, even during widespread shortages.

As a result, buyers may find prebuilt PCs available well before all the right parts for a custom build arrive. For those eager to get to work or play as soon as possible, prebuilt machines often present a more predictable and expedited option.

Warranty, Support, and Troubleshooting

After making an investment in a new PC, the experience of dealing with breakdowns or seeking help can greatly influence satisfaction. The type of warranty, support structure, and troubleshooting options can vary widely between custom and prebuilt systems.

Buyers should consider how much value they place on convenience, response time, and self-reliance when weighing their options.

Coverage Scope

Prebuilt PCs usually come with a single-system warranty that covers the entire machine, offering a straightforward path if something goes wrong. One point of contact simplifies the process, as the assembler or retailer often handles diagnosing and fixing issues within the warranty period.

In contrast, a custom-built PC has individual warranties for each major component. Tracking coverage for multiple parts, such as CPU, GPU, or power supply, requires additional recordkeeping.

The responsibility for diagnosing which piece has failed and pursuing each manufacturer falls directly on the user, which can be manageable for some but stressful for others.

RMA Logistics

Returning merchandise for repair or replacement, called RMA, also differs between formats. Prebuilt owners often need to send back the entire system for service, even if only one part is at fault.

This can lead to longer wait times without a computer, but the process is less technically demanding. With custom PCs, diagnosing a faulty component may allow the user to send back just the problematic part, keeping the rest of the system operational or substituting a backup part if available.

However, isolating the issue requires troubleshooting skills and potentially a deeper knowledge of hardware.

Customer Service & Community Help

Support for prebuilt PCs is usually handled through company hotlines, online chat portals, or email. Professional assistance offers quick answers and guided solutions for users who want a hassle-free experience.

For custom PCs, while manufacturers offer their own product support, much of the troubleshooting and optimization help comes from enthusiast communities. Online forums, Reddit threads, and countless YouTube tutorials walk users through hardware and software fixes, sometimes providing faster or more detailed guidance than official customer service channels.

Those willing to seek out answers can find a wealth of resources, though the learning curve may be steep for beginners.

Upgradeability & Future-Proofing

Considering a PC’s ability to adapt to future needs can make a big difference in the long run. The construction choices made at the outset play a powerful role in determining whether a system can be updated easily, and whether upgrades remain cost-effective as technology marches forward.

Buyers who want their machine to grow with them should pay close attention to the flexibility of hardware and case design.

Proprietary vs Standard Components

A major dividing line appears with motherboards, power supplies, and other foundational parts. Many custom PCs use industry-standard form factors, allowing users to mix and match parts from numerous manufacturers.

BIOS updates tend to be more frequent and better supported, broadening compatibility with new CPUs or memory. Prebuilt systems sometimes feature proprietary motherboards, custom-shaped power supplies, or non-standard wiring that can lock users into upgrades from the original vendor, or rule out upgrades entirely.

Even BIOS updates may be limited or delayed, narrowing the window to adopt new hardware without replacing more of the system than expected.

Ease of Part Swaps

Swapping out components is smoother in systems designed from the ground up for access and interchangeability. Fully modular custom builds often provide open layouts, ample cable management routes, and standard mounting for all parts.

Prebuilt machines may come with tool-less features for drives or graphics cards, but other areas could be cramped or inaccessible, limiting how easily hardware can be swapped. Proprietary chassis and cables sometimes require creative workarounds, making DIY upgrades trickier than anticipated.

Long-Term Cost Efficiency

Stretching the value of a PC over several years often depends on incremental upgrades. Standard PCs allow owners to swap the graphics card, add RAM, or drop in a new processor without overhauling the rest of the build.

With rigid or proprietary prebuilts, upgrades sometimes require nearly full system replacements, erasing any initial savings and shortening practical lifespan. Factoring in future-proofing can reveal that flexibility and compatibility add genuine value, especially for buyers planning to keep their system for many years or through several product cycles.

Conclusion

Custom-built PCs and prebuilt systems each cater to different buyer profiles. Budget-conscious tinkerers often gravitate toward DIY builds, enjoying full control over component quality and prioritizing long-term value through upgradeable, standard parts.

Plug-and-play gamers, on the other hand, appreciate the convenience and quick setup of prebuilts, swapping potential customization for instant functionality and streamlined support. Professional creators might find custom builds appealing for their ability to fine-tune hardware choices for demanding workloads, while busy parents or those with minimal technical interest may value a ready-made system’s simplicity and manufacturer-backed warranty.

Both routes have unique strengths and compromises. Custom PCs reward time investment and technical skill with optimal performance and the flexibility to adapt over time.

Prebuilt systems deliver peace of mind through consolidated support, rapid deployment, and less risk for those with limited experience. In the end, the ideal path depends on how each buyer weighs cost savings, out-of-box performance, hands-on convenience, accessible support, and the potential for future upgrades.

All of these factors are shaped by individual needs, lifestyle, and tech ambitions.