Thermal Paste vs. Thermal Pad: Know the Difference

Every serious PC builder or electronics enthusiast eventually asks the same practical question: Which thermal interface material should I use: paste or pad? That thin layer connecting your processor to its cooler might seem like a simple detail, but it directly affects temperatures, system reliability, and even long-term performance.

Choosing the wrong option can mean the difference between a stable, cool-running machine and one plagued by thermal throttling or costly repairs down the road. By comparing thermal paste and thermal pads across areas like conductivity, application, maintenance, usage scenarios, and overall value, you can confidently select the best solution for your build and cooling needs.

Thermal Performance and Efficiency

Thermal performance lies at the heart of any cooling solution. Effective management of heat is essential for CPUs, GPUs, and other high-performance components to maintain stability and avoid unexpected shutdowns or permanent damage.

Thermal interface materials serve as bridges between heat-generating components and their heatsinks, helping transfer thermal energy away from sensitive electronics.

Conductivity Metrics

Thermal conductivity, measured in watts per meter-kelvin (W/mK), directly influences how quickly heat travels from a component to its cooler. Thermal pastes usually offer much higher conductivity, typically ranging from 7.5 to 12.6 W/mK.

This high conductivity means paste can transfer heat very efficiently, especially in systems where temperatures spike quickly, such as during gaming or heavy computational tasks.

On the other hand, thermal pads typically deliver conductivity values between 1 and 8 W/mK. Although some premium pads get close to entry-level pastes, most standard pads perform at the lower end of the range.

For everyday office workstations, standard desktops, or electronics where peak temperatures stay modest, pads can often handle the load without issue. However, anyone targeting extreme performance or operating under high thermal stress will benefit from the superior transfer rates that pastes provide.

Gap-Filling Capability

Perfectly flat surfaces rarely exist in practical electronics. Microscopic imperfections and air gaps are common, which can hinder efficient heat transfer.

Thermal paste excels here due to its viscous and semi-liquid nature that allows it to seep into tiny surface irregularities, filling microscopic voids with ease. This property ensures contact between the component and heatsink is as close to complete as possible, maximizing conductive potential.

Thermal pads, on the other hand, come in various thicknesses and compress to accommodate larger, more irregular gaps that paste cannot address effectively. In situations where surfaces are slightly misaligned or manufacturing tolerances vary, pads act not only as heat conductors but also as physical fillers, ensuring consistent pressure and contact across the area.

Heat Dissipation Impact

Heat dissipation during regular and extreme usage defines the real-world effectiveness of a thermal interface material. High-performance setups such as gaming rigs or overclocked PCs subject components to intense, sustained heat output.

Paste responds well under continuous load, allowing for lower peak temperatures and more headroom for performance tuning. Overclockers and enthusiasts often prefer paste for this reason, as it contributes to more aggressive cooling and stable operation under stress.

Pads, while reliable for moderate heat loads, may struggle to keep up during demanding scenarios. Their lower conductivity can result in slightly higher temperatures, potentially limiting performance during heavy gaming sessions or rendering tasks.

However, pads still excel in environments where consistency, ease of application, and sufficient cooling for standard workloads are valued over absolute peak performance. The choice often comes down to the demands of the application and the need for thermal headroom.

Application and Maintenance

Ease of installation and long-term upkeep can be just as important as raw thermal performance, especially for those building PCs for the first time or maintaining systems over the years. The method of applying thermal interface materials, their maintenance cycles, and the cleanup process all influence both the user experience and the ongoing reliability of your hardware.

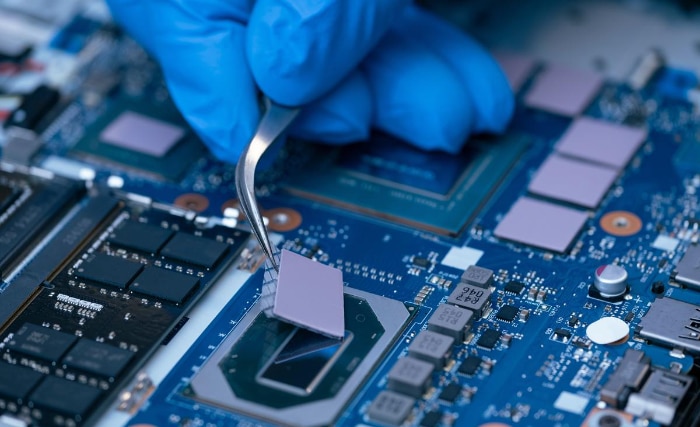

Installation Process

Applying thermal paste often demands precision and a steady hand. Users typically choose between the dot method, where a small amount is placed at the center of the processor, or the spread method, which involves evenly smoothing a thin layer across the surface.

Too much paste can spill over the edge, while too little may leave pockets of air that hinder heat transfer. A careful approach ensures full coverage with minimal mess and optimal effectiveness.

Peel-and-stick simplicity is where thermal pads shine. Installation usually involves nothing more than removing a protective film, placing the pad on the component, and assembling the heatsink.

No guesswork, spreading, or concerns about excess material. Pads come pre-cut or in sheets that can be trimmed to fit, which further streamlines the process. For large-scale assembly or anyone valuing a quick, mess-free experience, pads make the whole process straightforward.

Longevity

Thermal pastes can gradually dry out, especially after several years or under continuous thermal cycling. As paste loses moisture and becomes powdery or crusty, its thermal conductivity drops and reapplication may be necessary every two to five years for best results.

Enthusiasts or professionals who push their systems hard often factor regular reapplication into their maintenance routines.

Thermal pads, composed of more stable materials, generally retain their properties for longer periods. Pads are often reusable, provided they remain undamaged during disassembly and retain their compressibility.

For systems that stay assembled for years or in environments where minimal maintenance is preferred, pads offer a “set and forget” appeal that reduces long-term hassle.

Cleanup

Using thermal paste can get messy, especially during removal or reapplication. Residue often sticks to both the heatsink and component surface, requiring isopropyl alcohol and lint-free cloths for thorough cleaning.

The process may take some time, particularly if the paste has dried out or spread beyond the contact area.

Thermal pads offer a much cleaner solution. Pads can usually be peeled off cleanly with little or no residue left behind.

Any remnants are typically dry and easily removed, making reassembly or upgrades a more pleasant task. This user-friendly cleanup makes pads a logical choice for those prioritizing a tidy workspace or quick component swaps.

Use Case Suitability

Thermal interface materials must match the unique demands of the systems they serve. Users and technicians often choose between paste and pads based on performance goals, production requirements, or specialized needs.

Each application scenario highlights different aspects of their strengths and limitations, making the choice highly context-dependent.

High-Performance Systems

Gamers, overclockers, and professionals running demanding applications often push their hardware past standard specifications. For these setups, slightly lower temperatures can mean the difference between hitting a new performance milestone and facing instability or premature component wear.

Thermal paste remains the favorite for high-performance CPUs and GPUs, thanks to its superior thermal conductivity and ability to fill minute surface gaps. Efficient heat transfer enables processors and graphics cards to maintain lower operating temperatures, allowing for higher sustained clock speeds and longer sessions without throttling.

Custom PC builders and enthusiasts routinely select premium thermal pastes to maximize every bit of cooling potential, especially when investing in advanced cooling systems like liquid AIOs or custom water loops.

Production Environments

Mass manufacturing and assembly lines value consistency, speed, and reduced error rates. Thermal pads are engineered to meet these priorities, coming pre-cut for easy placement and sized for repeatable installations.

Workers can apply pads with minimal training, ensuring every unit in a production run receives the same thickness and coverage. Uniform application translates to reliable thermal performance across hundreds or thousands of devices.

Pads are especially common in laptops, small form factor PCs, networking equipment, and devices where efficiency during assembly outweighs squeezing out every possible degree of thermal performance. For businesses balancing output with quality, pads help standardize results while saving time.

Specialized Scenarios

Certain environments require more than just cooling. Electrical insulation may be necessary to prevent short circuits, or additional vibration resistance could be vital for systems subject to regular physical shocks.

Thermal pads, often made of silicone or other insulating materials, frequently deliver these secondary benefits. Their compressible structure can absorb vibrations that might damage delicate solder joints or components, helping extend device life in automotive, industrial, or mobile applications.

Pads also create a physical barrier that prevents electrical contact between components, valuable in compact electronics where parts are densely packed. In designs where thermal management must also address electrical or mechanical challenges, pads offer a practical and versatile solution.

Cost and Longevity Trade-offs

Choosing between thermal paste and thermal pads means weighing upfront costs, long-term value, required skill level, and risks associated with each option. Both materials offer unique advantages, but their long-term effectiveness and ease of use can impact not only how much you spend but also how often you need to revisit your cooling setup.

Budget, experience, and maintenance expectations all play important roles in determining the most practical solution for any given project.

Cost Analysis

Thermal paste generally delivers impressive value for money. A single tube ($5–$20) is affordable and often contains enough material for several applications ($1–$3 per application), making it an ideal choice for builders who maintain or upgrade multiple systems.

Price points remain low even for high-performance compounds, which helps keep build costs under control, especially for enthusiasts or budget-conscious users.

Thermal pads, on the other hand, usually command a higher price per application ($3–$15 per use). Their price reflects the convenience of pre-cut, ready-to-use materials ($10–$50+ per pack) and the added benefits like electrical insulation and vibration damping.

For users who only need one or two pads, the extra cost may be negligible compared to the time saved and the assurance of easy installation. In larger projects or manufacturing, though, expenses can add up quickly, particularly if pads with advanced features or custom shapes are required.

Skill Dependency

Applying thermal paste can be a rite of passage for new builders. The process requires careful attention: achieving the perfect amount and spreading it evenly is crucial for optimal thermal transfer.

Too much paste risks messy cleanup or reduced effectiveness, while too little can leave harmful air pockets. Experience and steady hands are assets in this scenario, making paste more appealing to those with confidence or prior practice.

Thermal pads essentially eliminate most of the challenges associated with user error. Straightforward peel-and-stick application makes them accessible to anyone, regardless of technical skill level.

New builders, system integrators, or those simply looking to avoid the fuss of perfecting their technique find pads especially attractive. Consistency is a major benefit, as every application delivers repeatable results without the learning curve.

Failure Risks

Reliability over time is critical for any thermal solution. Thermal paste can experience a phenomenon known as pump-out, where repeated thermal expansion and contraction cause the paste to migrate away from the crucial contact area.

Loss of coverage leads to gradual rises in component temperatures, often unnoticed until performance degrades or instability sets in. High-quality pastes mitigate this risk, but they do not eliminate it entirely.

Thermal pads come with their own potential drawbacks. Pads depend on proper compression to maintain effectiveness.

Over time, pads can lose their springiness, especially if subjected to repeated assembly and disassembly, or if the mounting pressure changes. Compression inconsistencies may lead to uneven contact and reduced thermal performance in the affected areas.

For both materials, monitoring system temperatures and inspecting the interface during maintenance helps prevent surprises and keeps your cooling solution reliable.

Conclusion

Finding the right thermal interface material means balancing more than just technical specifications; it is about matching performance with practical needs. Thermal paste consistently delivers peak cooling performance, excelling in high-demand environments such as gaming, overclocking, or professional workstations.

Its ability to fill microscopic gaps and transfer heat efficiently makes it the preferred choice for those pushing their hardware to its limits. However, application requires care and regular maintenance.

Thermal pads, in contrast, stand out for their durability, clean application, and user-friendly approach. Pads offer reliable thermal transfer for mainstream systems, laptops, and industrial setups where simplicity, consistency, or secondary benefits like electrical insulation are required.

They minimize the chance of installation error and reduce the need for frequent upkeep.

Choosing between paste and pads should never be a one-size-fits-all decision. The best results come from matching the material to the demands of your components, the level of cooling required, and your own comfort with installation.

Carefully weigh system needs, personal skill, and future maintenance to ensure your electronics run efficiently and reliably.